Products

Industries

- Irrigation

- Potable Water Supply

- Water & Waste Water

- Compact C Range

- De-Rag Muncher

- Discam

- ECO Pressure Sewer System

- Epsilon Range

- Extractors

- EZparts™

- EZstrip™ Cake Pump

- EZstrip™ TR Munchers

- EZstrip™ Transfer Pump

- Grifter

- InviziQ™ Pressure Sewer System

- L Series Discreen

- Macerator

- Munchpump

- Mutrator

- SB Muncher

- Series A Muncher

- Series F Muncher

- Stormscreen

- Widethroat W Range

- Food & Beverage

- Oil & Gas

- Chemicals & Pharmaceuticals

- Minerals & Mining

- Paper & Pulp

- Agriculture

- Solar

- General Industry/Other

- Community Development Solutions

- Potable Water Supply

EZstrip™ TR Munchers

CT201

A new addition to the EZstrip™ family of products, the CT201 TR Muncher® has been designed specifically to meet on-site tanker discharge requirements and sludge/fat processing, for maceration of solids within the flow and protection of downstream equipment from blockages.

Installation of the EZstrip™ CT201 TR Muncher® is simple, with in-line flanges or the option of tanker coupling connections. Quick release inspection covers also allow in-situ replacement of the cutters, which can be specified to either 8.0mm, 5.5mm and 3.0mm thickness, to match the optimum particle size for specific process requirements.

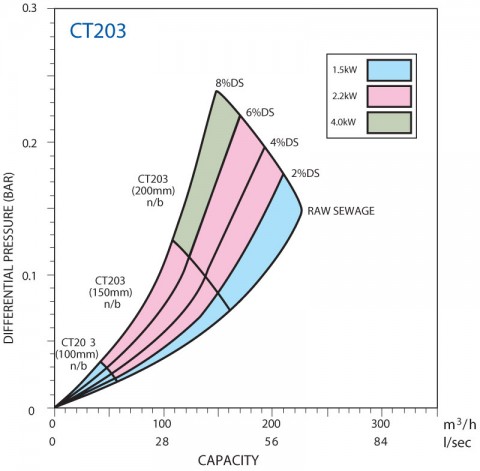

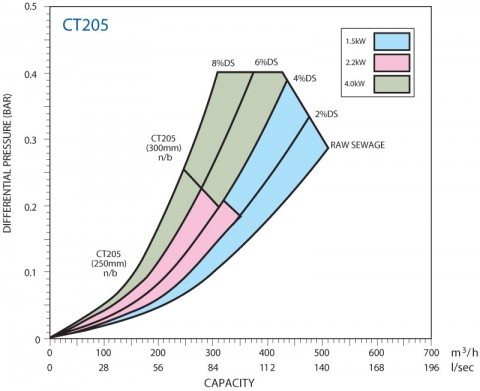

CT203/CT205

Designed specifically for the efficient maceration of abrasive sludges, the EZstrip™ CT203/05 TR Munchers are very effective in capturing irregular shaped objects. The layback cutter shafts on this Muncher are set at an angle to the incoming flow. If a rejection cycle is necessary, the object can drop into the built-in trash trap set clear of and below the cutter stacks, preventing damage. The trash trap is fitted with a large diameter access port to enable easy removal, cleaning and flushing.

| Capacity | Pressure | ||

|---|---|---|---|

| m³/h | 100 (CT201) 500 (CT203/205) | bar | 0.4 (CT203/205) |

| gpm | 440 (CT201) 2,200 (CT203/205) | psi | 5 (CT203/205) |

Applications

| Tanker reception | Pump protection. Fat/sludge conditioning |

| Abrasive sludge maceration - CT203/205 | Screenings in wash water - CT203/205 |

| Organic waste maceration - CT203/205 |

Features & Benefits

CT201

- A 'quick release access port allows the cutter assembly to be maintained in-place without removing the equipment and therefore reduces maintenance time.

- Rotational speed produces high torque, resulting in lower operating power at 1.5 or 2.2kW, which are available with energy efficient motors.

- Lower cutter tip speeds dramatically reduce wear rates. Slow speeds also ensure low noise and vibration, and good abrasion resistance.

- The off-loading requirements for 'on-stand' tankering are matched by the Munchers capacity.

- Pull-back cutter stack allows removal without disturbing the pipeline.

CT203/205

- Mono ETOS cutters offer positive and effective solids maceration

- Shafts operate at differential speeds to promote a tearing action on the solids

- Pull back cutter stack allows removal without disturbing the pipeline

- Cantilever shaft design eliminates the need for bottom bearings and seals, significantly reducing wearing components

- Patented built-in trash trap with clean-out ports to catch any rejected material

- Low cutter tip speeds, low power and low noise level

- Each Muncher is supplied with a programmable logic controller (PLC) to protect the machine against damage and overloads

- Munchers can be supplied to comply with the ATEX Directive 94/9/EC

NOV Australia Pty Ltd., 75 Frankston Gardens Drive,Carrum Downs, Victoria 3201 Australia

NOV Australia Pty Ltd., 75 Frankston Gardens Drive,Carrum Downs, Victoria 3201 Australia