Products

Industries

- Irrigation

- Potable Water Supply

- Water & Waste Water

- ABS Pumps

- Compact C Range

- De-Rag Muncher

- Discam

- Dosing Pump

- Epsilon Range

- Extractors

- EZparts™

- EZstrip™ Cake Pump

- EZstrip™ TR Munchers

- EZstrip™ Transfer Pump

- Grifter

- InviziQ™ Pressure Sewer System

- L Series Discreen

- Macerator

- Munchpump

- Mutrator

- SB Muncher

- Series A Muncher

- Series F Muncher

- Stormscreen

- Widethroat W Range

- Food & Beverage

- Oil & Gas

- Chemicals & Pharmaceuticals

- Minerals & Mining

- Paper & Pulp

- Agriculture

- Solar

- General Industry/Other

- Potable Water Supply

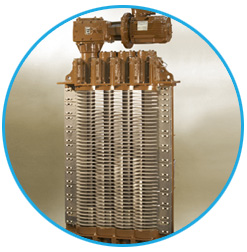

L Series Discreen

The Discreen design is self cleaning and does not blind or require manual raking or cleaning. The screen is constructed using a number of shafts, each fitted with discs that overlap and intermesh with corresponding shafts. The shaft rotation forms a gentle conveying action of solids across the face of the screen to the discharge point, whilst allowing water to flow through the disc stacks. Individual comb bars are fitted to the first and last shaft to eject screening solids for discharge back into the main flow or sump area.

With the ability to remove up to 95% of solids with 2.5mm, 5mm or 9.0mm aperture sizes, and a range of screens to fit various channel widths and depths, the Discreen gives you the flexibility for a large range of applications.

| Capacity | |

|---|---|

| m³/h | Up to 20,000 |

| gpm | Up to 88,057 |

Applications

| Pump station inlet | WwTW inlet |

| Storm water | Water abstraction |

Features & Benefits

- Intermeshing discs give a self cleaning screen area - no frequent raking and no secondary handling system

- Head losses are kept to a minimum and are consistent throughout the operation of the unit (unlike bar or mesh screens which can give high head losses between cleaning cycles)

- Low rotation speed, offers good resistance to abrasion

- Ability to remove up to 95% of solids with 2.5mm, 5mm or 9.0mm aperture sizes

- By combining a Discreen with a Mono Muncher, you have the option of keeping all macerated and screened residue in the main flow, eliminating removal costs

- Individual discs allow easy, low cost maintenance should they need replacing and allows screening capability to be changed for smaller screening of solids

Performance Data

* Based on a standard 10 shaft unit, for higher capacities consult Mono

1. These dimensions are for guidance only

2. For full certified drawings relating to installation details, please refer to Mono.

You must have flash player installed to view this video - download here: ![]()

Discreen Muncher

To protect downstream

Water Extraction

Discreen Video Clip.wmv

| Case Studies | |

|---|---|

| Waste Water: River water abstraction |

Mono Pumps (New Zealand) Ltd, 35-41 Fremlin Place, Avondale, Auckland, New Zealand

Mono Pumps (New Zealand) Ltd, 35-41 Fremlin Place, Avondale, Auckland, New Zealand