Products

Industries

- Irrigation

- Potable Water Supply

- Water & Waste Water

- ABS Pumps

- Compact C Range

- De-Rag Muncher

- Discam

- Dosing Pump

- Epsilon Range

- Extractors

- EZparts™

- EZstrip™ Cake Pump

- EZstrip™ TR Munchers

- EZstrip™ Transfer Pump

- Grifter

- InviziQ™ Pressure Sewer System

- L Series Discreen

- Macerator

- Munchpump

- Mutrator

- SB Muncher

- Series A Muncher

- Series F Muncher

- Stormscreen

- Widethroat W Range

- Food & Beverage

- Oil & Gas

- Chemicals & Pharmaceuticals

- Minerals & Mining

- Paper & Pulp

- Agriculture

- Solar

- General Industry/Other

- Potable Water Supply

Extractors

Extractors

When full extraction and washing of organic solids from inflows to sewage treatment works is needed, Mono can supply a number of solutions.

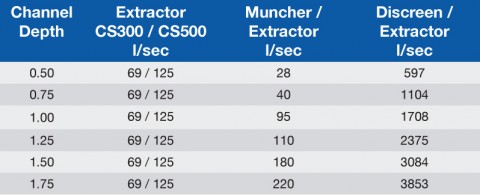

Our complete extraction package comprises three combinations of Discreen, Muncher and screw extractor for screenings removal.

Once solids have been screened and disintegrated by the Discreen and Muncher, the material collects on the perforated screen surface as the incoming water flows through it. A level switch operates the rotating screen spiral to run for the time necessary to clean the screen and convey the solids towards the discharge chute for removal.

Applications

| Inlet works |

Features & Benefits

- Consistent head losses create stable upstream and downstream depths

- Equipment and installation flexibility allows many different channel widths and depths to be covered

- Swivel support and an easily replaceable part of the spiral along the screen, simplify service and cut maintenance costs

- Minimum or no civil works required when fitting into existing channels

- Optional bagging and dewatering / compaction units available

| Case Studies | |

|---|---|

| Waste Water: Inlet channel, solids removal |

Mono Pumps (New Zealand) Ltd, 35-41 Fremlin Place, Avondale, Auckland, New Zealand

Mono Pumps (New Zealand) Ltd, 35-41 Fremlin Place, Avondale, Auckland, New Zealand