EZstrip™ Transfer Pump

EZstrip™ Transfer Pump

The EZstrip is the latest revolutionary new pump design which can be 'Maintained-in-Place' (MIP), making a day-long maintenance operation become a 30 minute job.

This innovative pump is the biggest leap forward in progressing cavity (PC) pump design for 30 years and is an extension of Mono's popular Compact C Range. The EZstrip has been specifically designed to provide a quick and easy way to disassemble, de-rag and maintain a PC pump in-situ, eliminating the costly maintenance and down time that servicing can often cause.

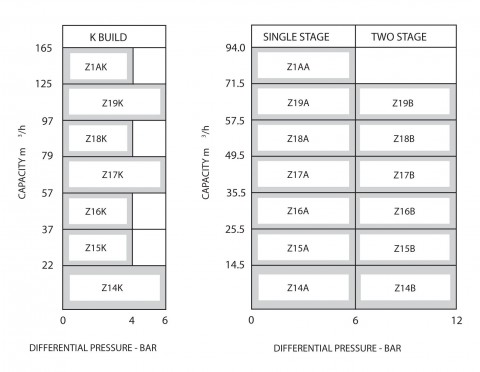

| Capacity | Pressure | Temperature | |||

|---|---|---|---|---|---|

| m³/h | 165 | bar | 12 | °C | -10 up to 100 |

| gpm | 726 | psi | 175 | °F | 14 up to 212 |

Applications

| Domestic effluents | Industrial effluents |

| Hydrated lime slurry | Sludge |

| Shear sensitive latex emulsion | Milk curds |

| Sauces | Fruit juices |

| Industrial chemicals and detergents | Starch slurries |

| Coating clays | Gypsum |

| Silicate | Paper stocks |

| Agricultural slurries |

Features & Benefits

- Available in cast iron or stainless steel, with a choice of rotor and stator materials, including WRAS compliant elastomers

- Quick and easy de-rag, in place

- Requires only spanners and an allen key to maintain

- Reduced maintenance downtime and labour savings

- No need to disconnect suction and discharge pipework

- Eliminates dismantling lengths

- Can be retrofitted into existing Compact C installations

- Operational parameters are unaffected

- A pre-assembled drive train is available, with 2 year warranty, to allow an even faster re-assembly time

NOV Australia Pty Ltd., 75 Frankston Gardens Drive,Carrum Downs, Victoria 3201 Australia

NOV Australia Pty Ltd., 75 Frankston Gardens Drive,Carrum Downs, Victoria 3201 Australia